TGDI gasoline engine, diesel engine assembly line, with the industry's senior technical engineering team and supporting resources, with the transmission line with the entire line of delivery capacity, the use of Europe and the United States Department of first-class OEM manufacturing engineering standards for customers tailored high-quality, High quality overall solution.

Including the short cylinder assembly line, the cylinder head packing, the piston connecting rod packing, the supercharger dispenser, the engine main assembly line, the thermal test and the hot test assembly line, equipped with the high precision high flexible bolt tightening machine, , The main oil leak test, robot coating, robot helium inspection high pressure tubing test and other core equipment, and integrated high intelligent MES manufacturing execution system.

Can be completed multi-series engine assembly and testing;

Can be completed multi-series engine assembly and testing;

Cylinder, cylinder head, crankshaft with flexible manipulator automatically on the line, effectively reduce the labor intensity and reduce the number of operators;

Cylinder, cylinder head, crankshaft with flexible manipulator automatically on the line, effectively reduce the labor intensity and reduce the number of operators;

Cylinder hole, crankshaft automatic oil lubrication, precise control of fuel injection and fuel injection location;

Cylinder hole, crankshaft automatic oil lubrication, precise control of fuel injection and fuel injection location;

Camshaft valve flapping, the use of engine real camshaft, real simulation beat order, beat the trip; low noise, effectively improve the operator's working environment;

Camshaft valve flapping, the use of engine real camshaft, real simulation beat order, beat the trip; low noise, effectively improve the operator's working environment;

Piston rod and cylinder collinear, operators do not need to turn, effectively reduce the labor intensity;

Piston rod and cylinder collinear, operators do not need to turn, effectively reduce the labor intensity;

Full floating piston pin ring automatic press fit, effectively improve the assembly quality and assembly efficiency;

Full floating piston pin ring automatic press fit, effectively improve the assembly quality and assembly efficiency;

Cross-channel high-altitude rotation, material delivery is completely smooth;

Cross-channel high-altitude rotation, material delivery is completely smooth;

Airtight lock piece of automatic press and laser detection, effectively improve the quality of valve lock assembly and assembly efficiency;

Airtight lock piece of automatic press and laser detection, effectively improve the quality of valve lock assembly and assembly efficiency;

Cylinder, cylinder head, crankshaft assembly line before the automatic cleaning, the effective protection of the assembly of cleanliness;

Cylinder, cylinder head, crankshaft assembly line before the automatic cleaning, the effective protection of the assembly of cleanliness;

Crankshaft before and after the use of automatic pressure packing, automatic detection of flatness, and effectively ensure the quality of oil seal assembly;

Crankshaft before and after the use of automatic pressure packing, automatic detection of flatness, and effectively ensure the quality of oil seal assembly;

The cylinder automatically code, the visual system to read the code, effectively guarantee the rate of qualified pass;

The cylinder automatically code, the visual system to read the code, effectively guarantee the rate of qualified pass;

Hot test area using intelligent RGV system automatically allocates materials, logistics and reduce the cost of customer equipment investment.

Hot test area using intelligent RGV system automatically allocates materials, logistics and reduce the cost of customer equipment investment.

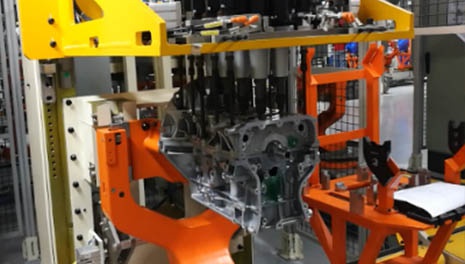

Cylinder head packing line

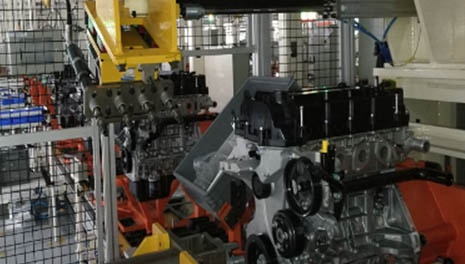

Piston rod assembly line

The engine cylinder head is loose

Motive cylinder tightened

Flywheel tightened

Piston reed

The pulley is tightened

Lock press

Leak test

Turn the line

The cylinder is tightened